Product filters

Filters

Loading products

Displaying 81 ... products

New Product

Regular price

$ 25.00

New Product

Slammer Waterproof Dry Backpack

Regular price

$ 89.00

New Product

Expedition Backpack

Regular price

$ 149.00

New Product

Lure Binder

Regular price

$ 39.00

New Product

Expedition Duffel Bag

Regular price

$ 179.00

New Product

Maxforce HD Harness

Regular price

$ 160.00

New Product

18L Waterproof Dry Bag

Regular price

$ 35.00

New Product

Maxforce Shoulder Harness

Regular price

$ 140.00

New Product

Standup HD Kit

Regular price

$ 360.00

New Product

Medium Reel Bag

Regular price

$ 119.00

New Product

Fighting Belt L

Regular price

$ 140.00

New Product

5L Waterproof Dry Bag

Regular price

$ 29.00

New Product

Fighting Belt XL

Regular price

$ 200.00

New Product

Large Reel Bag

Regular price

$ 149.00

New Product

Fixed Head Dehooker

Regular price

$ 140.00

New Product

Small Dehooker

Regular price

$ 35.00

New Product

Tag Stick Adaptor

Regular price

$ 49.00

New Product

Standup Shoulder Kit

Regular price

$ 220.00

New Product

Standup Lite Kit

Regular price

$ 230.00

New Product

Small Reel Bag

Regular price

$ 89.00

New Product

Maxforce Lite Harness

Regular price

$ 90.00

New Product

Whip Gaff

Regular price

$ 200.00

New Color

Breakwater Waterproof Gloves

Regular price

$ 59.00

New Color

65L Boat Bag

Regular price

$ 89.00

New Color

35L Boat Bag

Regular price

$ 69.00

New Color

+1

Solago Sun Gloves

Regular price

$ 29.00

New Color

Schoolie Backpack

Regular price

$ 69.00

Saiko Pro 100% Fluorocarbon Leader

Regular price

$ 13.00

Made In The USA

Titan Landing Net

Regular price

$ 349.00

Made In The USA

Aluminum Fishing Gaff

Regular price

$ 105.00

Fillet Knives

Regular price

$ 89.00

Circuit Breaker Ike Jime

Regular price

$ 29.00

Black Tapered Fiberglass Gaff

Regular price

$ 145.00

Alijos Fighting Belt

Regular price

$ 85.00

Tapered Fiberglass Gaff

Regular price

$ 103.00

Utility Glove

Regular price

$ 29.00

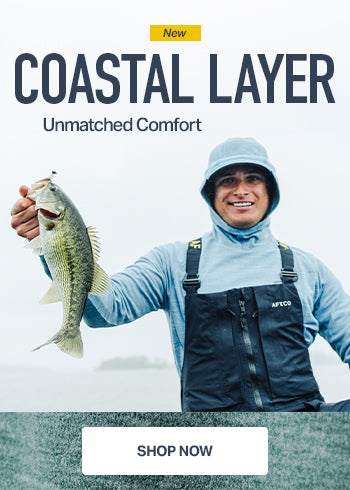

Precision-Built, High Performance Quality Offshore Fishing Tackle

The world's leading saltwater fishermen have long relied on AFTCO® fishing tackle components and fishing accessories for their consistently dependable, flawless performance. To preserve such a valued endorsement, we maintain a rigorous program of quality control over the creation of each and every product bearing the "AFTCO®" name.